New Life for Worn Artificial Grass Developed by MAS

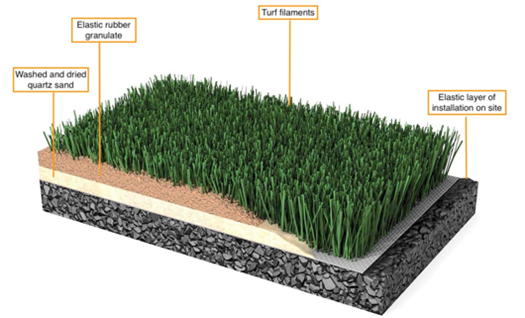

Although synthetic lawn had been introduced in American baseball stadiums already at the end of the 1960s, it only became an accepted alternative to the high-maintenance natural lawn at the turn of the millennium. But after 12-15 years of use, up to 5,000 artificial turf sports fields are currently due for renovation in Germany alone. This raises the question of the best possible disposal. Up-to-date the only serious answer is: “Recycling”. The Austrian extrusion and recycling technology company MAS offers innovative system technology for converting old and worn artificial grass efficiently and cost-effectively into high-quality plastic granulate.

Experience has shown that an artificial grass system can be in intense use for 12 to 15 years before it is due for renewal. And there is the question regarding the best possible disposal. As landfilling or thermal disposal in waste incineration are no longer accepted options due to the sharp increase in quantities there is no getting around recycling. Especially since better and more cost-effective methods are available to recycle almost 100 percent of the plastic and single-material systems are in the pipeline. The later in order to improve recyclability through the manufacture of the blades of the synthetic grass and the base fabric from the same material (PE) and to replace the method of connection by gluing by means of thermo-fixation. This will significantly simplify the technical efforts required for recycling. But as the single-material systems are just to be introduced they will be due for renewal only in 12 to 15 years. But until then, also conventional synthetic lawn can be recycled into valuable secondary raw materials.

The MAS-Recycling-Options

The renewal begins with the removal of the worn lawns (Fig.2). But before these can be removed and rolled up, the filling material (rubber granulate and sand) is to be vacuumed off. The better and more thoroughly these extraneous materials can be separated, the easier is the further processing of the old lawn. The next recycling step is the shredding down to particles 10 to 40 mm in length with a bulk density (uncompacted) of approx. 50 to 100 g/l (Fig. 3).

The shredded material consists of:

approx. 40% PE (the actual grass-blades)

approx. 20% PP (base fabric)

approx. 40% latex/natural rubber or PU (backing on the base fabric)

It contains up to 15 percent by volume of impurities, consisting of:

up to 8% extraneous materials (dust, sand, soil)

up to 1% rubber (old tire granulate) or EPDM from approx. 2 mm down to dust,

3 – 5% moisture

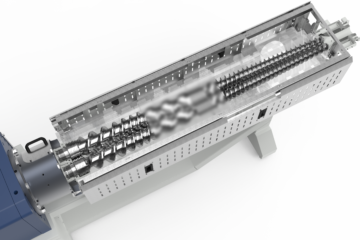

Material tests have shown that the MAS-system-technology is capable to process this

PE/PP-fiber-mixture into a high-quality plastic granulate. Their basic processing

component is the DRD (Double Rotary Disc) dry cleaner-unit.

To read more about the innovative technology and methods MAS utilise to recycle worn artificial grass, feel free to read the case study below.